Innovations in technology plays an important role in shaping the future of various industries. One such ground-breaking advancement that continues to revolutionize metalworking is laser cutting. The precision, speed, and versatility of laser cutting technology have transformed the landscape of metal sheet cutting, paving the way for unprecedented possibilities. In this blog, we will discuss the current state of laser cutting, its applications, and the exciting advancements that promise to shape the future of metal sheet cutting.

Current State of Laser Cutting:

Laser cutting, a process that uses a focused laser beam to cut through materials, has become an essential piece of equipment in the manufacturing industry. When it comes to metal sheet cutting, the precision offered by laser cutting machines is unparalleled. The technology utilizes high-powered lasers to melt, burn, or vaporize material, resulting in clean and precise cuts with minimal heat-affected zones.

Applications of Laser Cutting in Metal Sheet Cutting:

Automotive Industry: Laser cutting has become integral in the automotive sector for fabricating intricate components with high precision. Laser cutting assures precision and uniformity in production for anything from chassis elements to complex interior components.

Medical Equipment Manufacturing: Laser cutting is widely employed in the production of medical devices and equipment. Its ability to create complicated and small components with precision makes it ideal for manufacturing medical tools, implants, and components.

Architectural and Decorative Metalwork: Laser cutting has found its way into architectural design and decorative metalwork. From intricate metal panels to custom signage, the technology allows for the creation of detailed and aesthetically pleasing designs in metal sheets.

Advancements in Laser Cutting Technology:

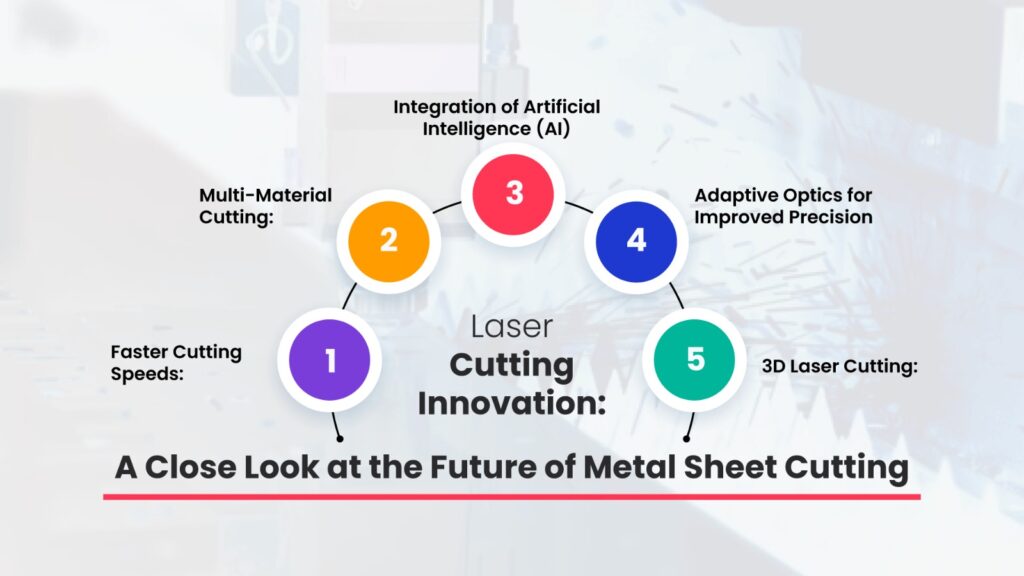

Faster Cutting Speeds: The pursuit of enhanced productivity and efficiency has resulted in constant progress in laser cutting speeds. Innovations in laser source technology and machine design are facilitating faster cutting speeds without compromising precision.

Multi-Material Cutting: Future laser cutting systems are expected to handle a broader range of materials seamlessly. This includes a more efficient cutting of reflective materials like copper and brass, expanding the application of laser cutting across various industries.

Integration of Artificial Intelligence (AI): The integration of AI in laser cutting machines is on the horizon. AI algorithms can enhance the decision-making process during cutting operations, optimizing parameters for different materials and improving overall efficiency.

Adaptive Optics for Improved Precision: The use of adaptive optics in laser cutting is anticipated to improve precision by dynamically adjusting the laser beams characteristics based on real-time feedback. This technology ensures optimal focus and energy distribution, resulting in enhanced cut quality.

3D Laser Cutting: The future of metal sheet cutting is likely to witness a shift towards 3D laser cutting. This innovation allows for the fabrication of complex three-dimensional components, opening up new possibilities in design and manufacturing.

Conclusion:

As we delve into the future of metal sheet cutting, the trajectory of laser cutting innovation is undeniably exciting. From improved cutting speeds to the integration of AI and the advent of 3D laser cutting, the landscape of metalworking is set to undergo transformative changes. These advancements not only promise increased efficiency and precision but also open up new avenues for creative and intricate metal designs. As manufacturers embrace these innovations, the future of metal sheet cutting appears to be a fusion of precision, speed, and limitless possibilities.

Pingback: Laser Cutting Innovation: A Close Look at the Future of Metal Sheet Cutting – Laser Cutting Services